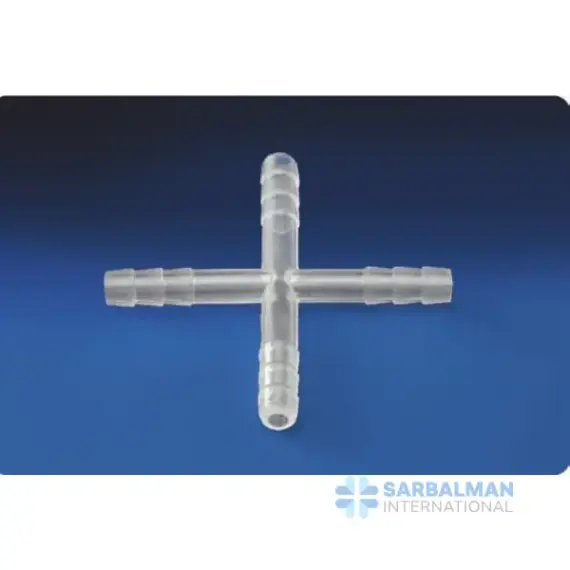

Connectors (Cross)

Free!

Cross connectors are four-way hose fittings that split or combine flow in a compact junction. The tapered barbs grip tubing securely, while smooth bores support clean, low-turbulence transfer. Use them to branch buffers, route wash lines, or merge streams without bulky manifolds. They’re lightweight, non-corroding, and easy to reconfigure—ideal for research labs, QC suites, pilot rigs, and any setup that needs neat, reliable distribution.

Description

A cross connector is a four-way hose fitting used to split or combine flow in tubing systems. Each arm accepts flexible tubing, creating a compact junction for liquids or gases at low to moderate pressure. Cross connectors keep bench setups tidy, reduce kinks, and make it easy to branch a single source into multiple lines or merge streams before the next step. They are commonly molded with tapered barbs for a secure grip and smooth internal bores to minimize turbulence.

Key features and benefits:

• Four-way junction for clean distribution or collection of flows

• Tapered, ribbed barbs help prevent leaks and tubing slippage

• Smooth internal passages to reduce hold-up and improve rinsing

• Available in common lab materials (e.g., polypropylene, nylon, PVDF, PTFE) to suit chemical and temperature needs

• Lightweight, non-corroding, and easy to assemble without tools

• Offered in multiple bore sizes to match common tubing IDs

Common use cases and industries:

• Reagent and buffer distribution in research, QC, and bioprocess labs

• Sampling manifolds in environmental and food testing

• Wash lines, drain manifolds, and dosing networks on pilot rigs

• Educational labs for modular, visible flow paths

Comparison guidance:

• Versus T or Y connectors, a cross creates two perpendicular branches, reducing extra fittings and conserving space

• Versus metal manifolds, plastic crosses are lighter, non-reactive with many media, and easier to reconfigure

Quality notes:

• Choose material for chemical compatibility, working temperature, and sterilization method

• Confirm pressure ratings and documentation (material grade, lot traceability) where required by SOPs