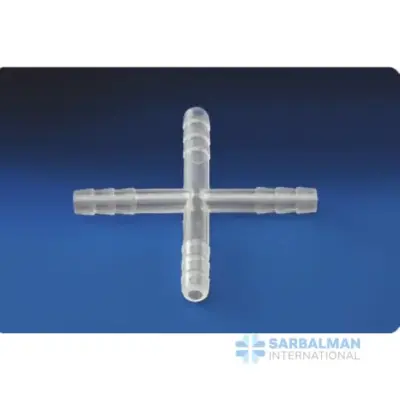

Connectors (L Shaped)

Free!

L-shaped connectors are right-angle hose fittings that turn flow 90 degrees without kinking the tubing. They save space, reduce backpressure, and create tidy, leak-resistant routing for liquids or gases. Choose them for instrument hookups, buffer and wash lines, and tight enclosures where neat corners matter more than branching. Available in multiple materials to match your chemical and temperature needs, they assemble quickly and keep systems clean and reliable.

Description

An L-shaped connector is a right-angle hose fitting used to change flow direction by 90 degrees without sharply bending the tubing. It creates a compact elbow that preserves internal diameter, reduces kinks, and keeps benchtop or equipment layouts tidy. Each end accepts flexible tubing and typically features tapered barbs or threaded ends for a secure, leak-resistant joint. In labs and light process work, L-shaped connectors help route liquids or gases around corners, panels, and crowded instrument spaces while maintaining smooth flow.

Key features and benefits:

• 90° turn without kinking: preserves flow and reduces backpressure

• Space-saving geometry organizes lines in racks, enclosures, and tight benches

• Leak-resistant ends: barbed or threaded options to match common tubing and fittings

• Smooth internal bore minimizes turbulence and hold-up volume

• Multiple materials available (e.g., polypropylene, nylon, PVDF, PTFE) to fit chemical, temperature, and sterilization needs

• Lightweight, corrosion-free, and easy to assemble—often tool-free with hose clamps as needed

Common use cases and industries:

• Routing buffer, wash, and waste lines in research and QC labs

• Instrument hookups for HPLC, chromatography skids, and environmental samplers

• Pilot rigs, bioprocess utilities, and dosing systems where neat, predictable routing matters

• Educational labs and makerspaces for clear, modular flow paths

Comparison guidance:

• Versus straight connectors, L-shaped elbows prevent sharp bends and extend tubing life in corners

• Versus T connectors, elbows focus on directional change rather than branching, limiting dead legs and simplifying cleaning

• Versus metal elbows, plastic options are lighter, non-reactive with many media, and easier to reconfigure

Quality notes:

• Select material for chemical compatibility and temperature range

• Verify pressure limits, sterility approach, and any required documentation per your SOPs