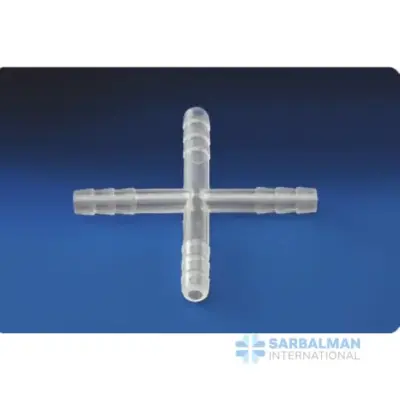

Plastic Stopcocks & Connectors

Free!

Description

Plastic stopcocks and connectors are essential components used in laboratories, medical facilities, and industrial applications to control, direct, or join the flow of liquids and gases. Made from durable polymers like polypropylene or polycarbonate, these devices are lightweight, corrosion-resistant, and designed to withstand repeated use. A stopcock functions as a miniature valve, allowing users to start, stop, or regulate flow with precision, while connectors link tubing and equipment securely, ensuring leak-free transfer. Together, they form the backbone of many fluid-handling systems.

Key features and benefits

• Flow control: stopcocks provide smooth, adjustable flow regulation, available in one-way, two-way, and three-way designs.

• Leak prevention: precision-molded connectors create tight seals with standard lab or medical tubing.

• Chemical resistance: compatible with many aqueous solutions, buffers, and mild chemicals.

• Lightweight and strong: plastic construction resists breakage, unlike glass, and is more affordable than metal.

• Versatility: connectors available in Luer, barbed, and threaded styles to fit diverse tubing systems.

• Sterilization options: many models are autoclavable for reuse in sterile environments.

Common uses and applications

• Medical setups: IV lines, infusion systems, and other fluid-transfer devices.

• Laboratory workflows: chromatography, titration, filtration setups, and reagent distribution.

• Industrial fluid control: chemical testing, food and beverage quality control, and pilot plant operations.

• Educational settings: safe, low-cost tools for teaching fluid mechanics and lab techniques.

Comparison and selection tips

• Plastic vs glass/metal: plastic is safer, cost-effective, and shatter-resistant; glass tolerates high heat better; metal offers extreme durability for industrial demands.

• Connector styles: barbed connectors grip tubing tightly, Luer locks provide standardized fittings for medical use, and threaded connectors allow secure, high-pressure applications.

• Stopcock design: two-way models suit simple flow control, while three-way stopcocks enable switching between multiple lines.

Quality and compliance context

• Many plastic stopcocks and connectors are manufactured to meet laboratory or medical quality standards, ensuring safe and reliable performance.

• Proper cleaning, sterilization, and inspection before use are recommended to maintain function and prevent contamination.